Manufacturing Operations Applet

Purpose and Overview

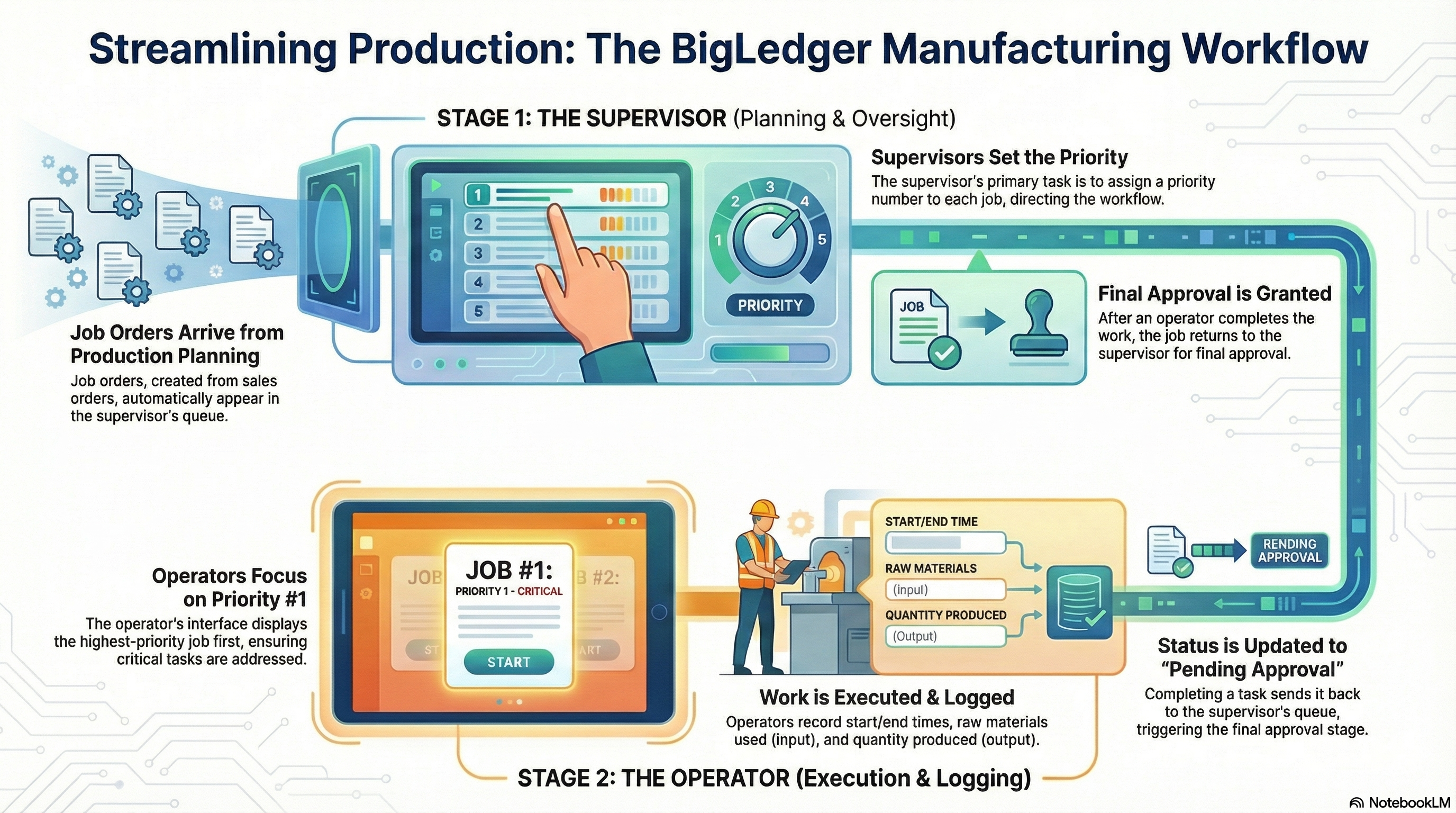

The Manufacturing Operations Applet is your shop floor execution hub where production actually happens. It takes the Job Orders created in the Production Planning & Monitoring (PPM) Applet and turns them into finished goods through structured work logging, material tracking, and supervisor approval.

Who Uses This Applet

Machine Operators:

- Claim and execute assigned jobs

- Record time, materials, and measurements

- Enter production quantities

- Report discrepancies

Production Supervisors:

- Set job priorities

- Review and approve work logs

- Manage process status

- Ensure quality compliance

Key Features Overview

How It Works: The Execution Flow

Job Order (From PPM Applet)

↓

Supervisor Sets Priority (Supervisor PI)

↓

Operator Claims Job (Operator PMC)

↓

Work Log Created (Time, Materials, Measurements)

↓

Production Completed (Output Recorded)

↓

Supervisor Approves (Quality Gate)

↓

Transfer to Internal PackingKey Concepts

| Concept | What It Means | Example |

|---|---|---|

| Process Instance | Individual manufacturing step from Job Order | “Armoring” step for JO-2024-001 |

| Work Log | Record of production activity | Time spent, bins used, quantity produced |

| Bin | Specific inventory container/location | BIN-RAW-001 containing steel wire |

| Priority Number | Job sequence ranking | 1 = highest priority, larger = lower |

| Discrepancy | Difference between planned and actual output | Planned 1000, produced 800 = 200 discrepancy |

| Ready Status | Supervisor-approved, ready for next stage | Process complete, transfer to packing |

Prerequisites: From Planning to Execution

| Required Setup | Where It Happens | What It Provides |

|---|---|---|

| Job Orders | PPM Applet | Manufacturing instructions |

| Process Instances | PPM Applet (Generate) | Individual steps to execute |

| Material Availability | Inventory | Bins with raw materials |

| User Permissions | User Management | Operator and Supervisor access |

Checklist Before Execution:

- Planner has created Job Order in PPM

- Process Instances have been generated

- Required materials are available in bins

- Operators have system access

- Supervisors have “MRP supervisor” permission

Applet Structure: Two Role-Based Menus

| Menu | Role | Purpose |

|---|---|---|

| Supervisor PI | Production Supervisor | Set priorities, review logs, approve processes |

| Operator PMC | Machine Operator | Claim jobs, record work, enter production data |

1. Supervisor PI: Managing the Production Queue

The Supervisor PI (Process Instance) menu is your command center for controlling what gets produced and when, and for ensuring quality through work log approval.

Setting Job Priorities

Operators see jobs ordered by the priority you set here. This is how you control the production sequence.

Steps:

- Open Supervisor PI

- Select an active Job Order

- Enter a Priority Number

Priority Logic:

| Priority | Meaning | When to Use |

|---|---|---|

| 1 | Highest priority | Rush orders, customer escalations |

| 2-10 | High priority | Important deadlines |

| 11-50 | Normal priority | Standard production |

| 51+ | Low priority | Fill-in work, no deadline |

Reviewing and Approving Work Logs

When an operator completes a task, it appears as Pending Approval. This is your quality gate.

Review Checklist:

- Verify time entries are reasonable

- Check correct bins were selected

- Confirm measurements are within spec

- Validate output quantity

Status Actions:

| Action | When to Use | Result |

|---|---|---|

| Ready / Completed | Work log is accurate and complete | Process moves to next stage or packing |

| On Hold | Issue needs resolution | Pauses production (machine issue, QA check) |

| Cancelled | Process should not continue | Terminates the process instance |

Handling Corrections

If an operator made an error in a saved Work Log:

Before marking Ready:

- Supervisor can edit the log directly, OR

- Revert status to In Progress for operator correction

After marking Ready:

- Contact system administrator

- May require inventory adjustment

2. Operator PMC: Executing Production

The Operator PMC (Production Management Console) is where you translate physical production into digital records. Accuracy here drives inventory, costing, and traceability.

Viewing Your Work Queue

Navigate to Operator PMC to see jobs assigned to you or your machine.

Queue Organization:

- Jobs appear in priority order (lowest number = highest priority)

- Filter by Machine Code if needed

- Status shows current state of each process

Status Indicators:

| Status | Meaning | Your Action |

|---|---|---|

| Available | Ready to claim | Claim and start work |

| In Progress | Currently being worked | Continue or complete |

| Pending Approval | Waiting for supervisor | Wait for approval |

| Ready | Approved, moving forward | No action needed |

Claiming a Job

Before you can record work, you must claim the job.

Steps:

- Open Operator PMC

- Locate your job (highest priority at top)

- Change status from Claim → In Progress

Creating a Work Log

Click the "+" icon to create a Work Log. This is the most critical step for production accuracy.

Required Inputs:

Time Tracking

| Field | Action | System Behavior |

|---|---|---|

| Start | Click when work begins | Records start timestamp |

| End | Click when work stops | Records end timestamp |

| Total Time | Automatic | Calculates End - Start |

Material Input (Bin Selection)

Select the exact bins used for raw materials. This creates traceability from raw material to finished good.

Steps:

- View required input materials

- Select specific bin(s) containing those materials

- Confirm quantities consumed

Measurements

Enter required specifications for quality control.

Common Measurements:

- OD (Outer Diameter) - Start, Mid, End

- Length measurements

- Weight specifications

- Visual inspection results

All measurements should follow defined standards (e.g., OD in millimeters).

Quantity Produced

Enter the final produced quantity.

Options:

- Single entry for one output container

- Bulk Add if output is split across multiple reels or bins

Discrepancy Handling:

The system automatically calculates discrepancy:

Discrepancy = Planned Quantity - Actual Quantity| Scenario | Example | System Records |

|---|---|---|

| On Target | Planned 1000, Produced 1000 | No discrepancy |

| Under Production | Planned 1000, Produced 800 | 200 unit discrepancy |

| Over Production (Surplus) | Planned 1000, Produced 1050 | 50 unit surplus |

Surplus remains in stock for future orders.

3. Work Log Best Practices

Data Quality Standards

| Data Element | Standard | Example |

|---|---|---|

| Job Order | Format: Year/Month/Day sequence | JO-2024-0115 |

| Measurements | All in millimeters | OD: 12.5mm |

| Time | Actual work time only | Exclude breaks |

| Bins | Exact bin codes | BIN-RAW-001 |

Common Mistakes to Avoid

Time Recording:

- ❌ Clicking Start when claiming job (inflates time)

- ✅ Clicking Start when production actually begins

Bin Selection:

- ❌ Selecting any available bin

- ✅ Selecting the exact bin you’re physically using

Quantity Entry:

- ❌ Entering planned quantity instead of actual

- ✅ Counting/measuring actual output

Measurements:

- ❌ Skipping measurements or entering estimates

- ✅ Taking actual measurements at specified points

4. Process Status Lifecycle

| Status | Set By | Meaning | Next Step |

|---|---|---|---|

| Available | System | Ready for operator | Operator claims |

| In Progress | Operator | Work underway | Complete work log |

| Pending Approval | Operator | Work log submitted | Supervisor reviews |

| Ready | Supervisor | Approved | Transfer to packing |

| On Hold | Supervisor | Paused for issue | Resolve and resume |

| Cancelled | Supervisor | Terminated | Document reason |

Status Flow:

Available → In Progress → Pending Approval → Ready → Packing

↓

On Hold → Resume → Pending Approval5. Integration with Other Applets

From PPM Applet (Upstream)

| What Comes In | How It’s Used |

|---|---|

| Job Orders | Defines what to produce |

| Process Instances | Individual steps to execute |

| Material Requirements | What bins to select |

| Priority Flags | Initial priority guidance |

To Internal Packing (Downstream)

| What Goes Out | When It Transfers |

|---|---|

| Completed Process | After supervisor marks Ready |

| Output Quantity | Recorded in work log |

| Quality Data | Measurements and approvals |

Inventory Updates

| Action | Inventory Effect |

|---|---|

| Bin Selection | Reserves/consumes raw materials |

| Output Recording | Creates finished/semi-finished goods |

| Discrepancy | Adjusts expected vs actual |

6. Settings and Permissions

User Permissions

| Permission | Role | Grants Access To |

|---|---|---|

| Default | Operator | Operator PMC menu |

| MRP supervisor | Supervisor | Supervisor PI menu |

Machine Code Configuration

Each Work Log is tied to a specific Machine Code.

Rule: One Work Log per Machine Code per process instance.

This ensures accurate machine-hour reporting and maintenance tracking.

7. Common Issues

Job Order not visible in Operator list?

- Check if Process Instances were generated in PPM

- Verify correct Machine Code filter

- Confirm job has been released

Can’t create Work Log?

- Job must be in “In Progress” status

- Claim the job first

Wrong quantity entered in saved Work Log?

- If not yet “Ready”: Supervisor can edit or revert to In Progress

- If already “Ready”: Contact administrator

Supervisor PI menu not visible?

- Enable “MRP supervisor” permission in user profile

- Re-login after permission change

Time calculation seems wrong?

- Verify Start and End times are correct

- Check for accidental double-clicks

- Supervisor can edit before approval

Bin not appearing in selection?

- Verify bin has available stock

- Check bin is for correct item

- Confirm bin is active in inventory

8. Quick Reference

Supervisor Daily Routine

Start of Shift:

- Review incoming Process Instances from PPM

- Set priorities based on deadlines and urgency

- Communicate priorities to operators

During Shift:

- Monitor work queue progress

- Review and approve completed work logs

- Handle On Hold situations

- Adjust priorities as needed

End of Shift:

- Approve all pending work logs

- Review discrepancies

- Update PPM on completion status

- Prepare handover notes

Operator Daily Routine

Start of Shift:

- Check work queue in Operator PMC

- Review priority order

- Gather materials for first job

For Each Job:

- Claim job → In Progress

- Click Start when beginning work

- Select correct input bins

- Perform production

- Enter measurements

- Click End when complete

- Enter quantity produced

- Submit for approval

End of Shift:

- Complete current work log

- Do not leave jobs “In Progress” without work log

- Report any issues to supervisor

Key Actions Summary

| Task | Role | Where | How |

|---|---|---|---|

| Set job priority | Supervisor | Supervisor PI | Enter priority number |

| Approve work log | Supervisor | Supervisor PI | Review and mark Ready |

| Claim job | Operator | Operator PMC | Change to In Progress |

| Record time | Operator | Work Log | Click Start/End |

| Select materials | Operator | Work Log | Choose bins |

| Enter output | Operator | Work Log | Enter quantity, Bulk Add if needed |

| Submit for approval | Operator | Work Log | Save and submit |

Related Documentation

Manufacturing Ecosystem

- Production Planning & Monitoring Applet - Job Order creation and planning

- Process Maintenance Applet - Process templates and machine setup

- Manufacturing Module - Complete module overview

Supporting Applets

- Stock Balance Applet - Inventory visibility

- Internal Stock Adjustment Applet - Inventory corrections