Process Maintenance Applet

Purpose and Overview

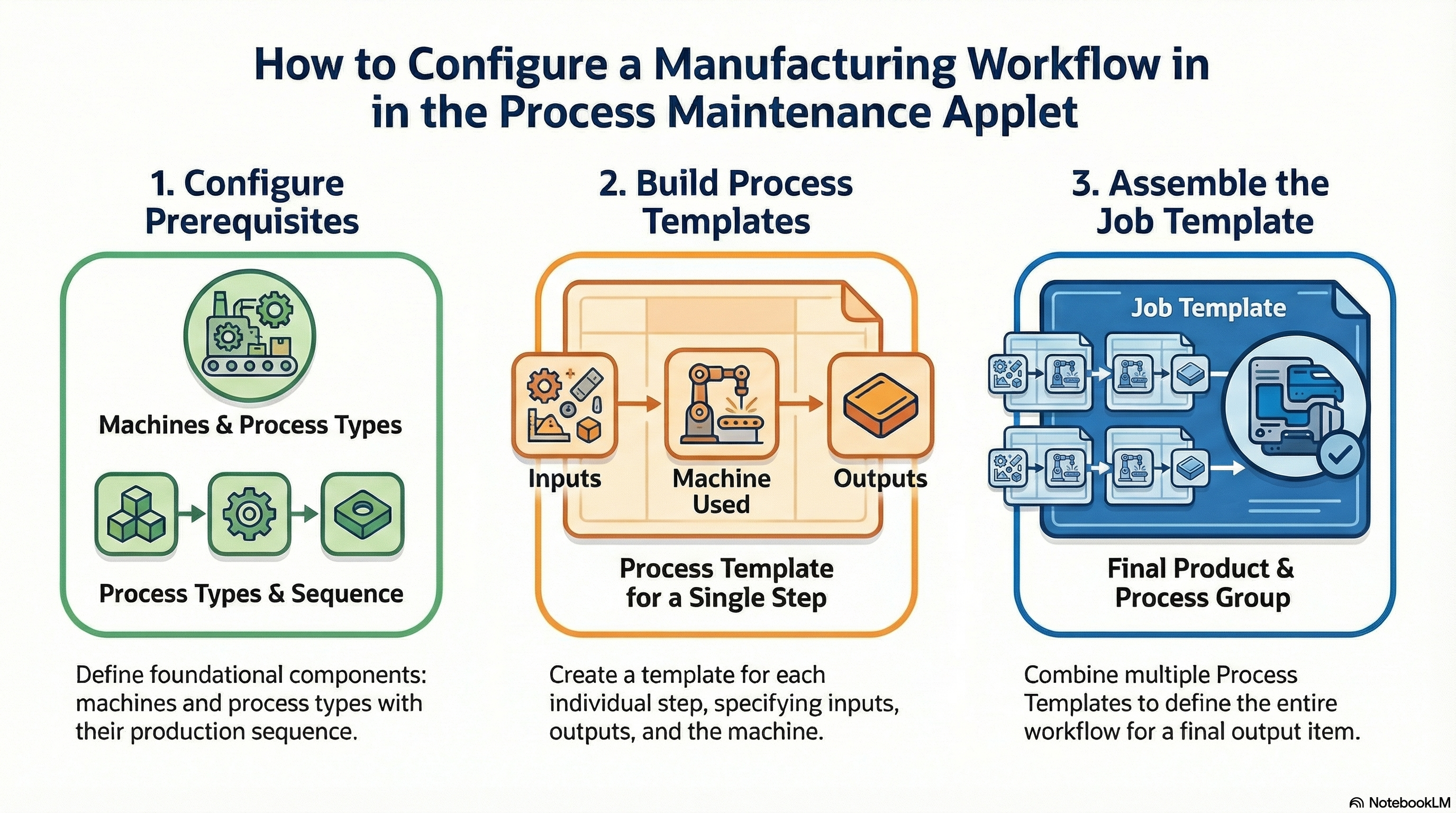

The Process Maintenance Applet is where you define how your factory makes things. It’s the foundation layer that the Production Planning & Monitoring Applet builds on—without proper process configuration here, you can’t create Job Orders there.

Think of it as your manufacturing knowledge base: which machines do what, what materials go into each step, what comes out, and how steps combine into complete production sequences.

Who Uses This Applet

System Administrators:

- Initial setup of Machines and Process Types

- Define production capabilities

- Configure equipment specifications

Production Engineers:

- Create Process Templates (individual manufacturing steps)

- Build Job Templates (complete production sequences)

- Define input/output ratios and material requirements

Cost Accountants:

- Verify material consumption ratios

- Validate production costing accuracy

- Review input/output relationships

Key Features Overview

Key Concepts

| Concept | What It Means | Example |

|---|---|---|

| Machine | Physical production equipment | Armoring Machine A1, Cutting Line B2 |

| Process Type | Category of manufacturing operation | Cutting, Assembly, Testing, Packaging |

| Process Template | Single manufacturing step with inputs/outputs | “Armoring Process”: Steel wire (input) → Armored cable (output) |

| Job Template | Complete production sequence | “Armored Cable Job” = Armoring + Bedding + Cabling |

| Input Items | Materials consumed in a process | Raw materials, semi-finished goods |

| Output Items | Products created by a process | Semi-finished goods, finished products |

| Ratio | Quantity relationship | 4 legs (input) → 1 table (output) |

How It Works: The Configuration Flow

Machines + Process Types (Resources)

↓

Process Templates (Individual steps with inputs/outputs)

↓

Job Templates (Complete production sequences)

↓

Used by Production Planning Applet

↓

Job Orders created for factory floorPrerequisites: Item Master Data

The Process Maintenance Applet can only reference items that are already registered in the system. If you try to add an input or output item that doesn’t exist, it won’t appear in the search.

Required Setup:

- Create all items in Item Data Hub

- Activate items in Doc Item Maintenance

- Then proceed with process configuration

1. Machine Configuration

Machines are your physical production assets. Define them once, then reference them in Process Templates.

Creating Machines

Navigate to the Machine menu and create entries for each piece of equipment on your factory floor.

Name/Code - Unique identifier for the machine. Use a consistent naming scheme that makes sense to your operators (e.g., “ARM-A1” for Armoring Machine A1, “BED-B2” for Bedding Line B2).

Type - Categorizes the machine’s function:

- Production Machine - Primary manufacturing equipment (cutting, assembly, processing)

- Packing Machine - Packaging and finishing equipment

The Type field helps with filtering and reporting but doesn’t restrict what processes can use the machine. That’s controlled at the Process Template level.

2. Process Type Configuration

Process Types categorize your manufacturing operations and define their sequence in production flows. This is where you establish the order of operations.

Creating Process Types

Navigate to the Process Type menu. Each Process Type represents a category of work.

Name - The operation category (Armoring, Bedding, Cabling, Testing, Packaging, etc.)

Sequence - This number determines the default order when Process Templates are combined into Job Templates. Lower numbers happen first.

Use gaps in your numbering (10, 20, 30, 40) rather than consecutive numbers (1, 2, 3, 4). This gives you flexibility to insert new process types later without renumbering everything. If you need to add a process between Armoring (10) and Bedding (20), you can use 15.

Independent Process - Check this for operations that don’t follow the standard sequence. Examples:

- Daily maintenance routines

- Quality inspections that can happen at any time

- Parallel operations that don’t depend on previous steps

3. Process Template Creation

Process Templates are individual manufacturing steps. Each one defines what goes in (inputs), what comes out (outputs), and which machines can perform the work.

Creating a Process Template

Navigate to Process Template menu and create a new template.

Template Name - Be descriptive and consistent. Good naming helps everyone understand what the process does at a glance.

Naming Convention:

[Department] - [Action] - [Target]

Examples:

- "Cable Dept - Armoring - 10mm Cable"

- "Wood Shop - Cutting - Oak Panels"

- "Assembly - Table Legs - Standard"Process Type - Select from the types you created earlier. This determines where this step fits in the production sequence.

Defining Input and Output Items

This is the critical part—the recipe that drives material consumption and inventory transactions.

Output Items Tab:

Add the item(s) this process creates. For each output:

- Select the item code

- Define the ratio (quantity produced per cycle)

Example: If one cycle produces 5 meters of cable, the ratio is 5.

Input Items Tab:

Add the materials consumed. For each input:

- Select the item code

- Define the ratio (quantity consumed per cycle)

Example: If producing 5 meters of cable requires 5.2 meters of raw wire (accounting for waste), the ratio is 5.2.

Ratio Logic is Critical:

The system uses these ratios to calculate material requirements when Job Orders are created. If your ratios are wrong, your inventory will be wrong.

Example: Table Assembly

Output: 1 Table (ratio = 1)

Inputs:

- 1 Table Top (ratio = 1)

- 4 Table Legs (ratio = 4)

- 8 Screws (ratio = 8)

- 1 Instruction Sheet (ratio = 1)Machine Assignment

In the Machine tab, select which equipment can perform this process.

If multiple machines are capable (e.g., you have three identical cutting machines), check all of them. This gives the factory floor flexibility in machine assignment.

Set one as Default - This is the machine that will be pre-selected when Job Orders are created. Choose your primary or most efficient machine.

Machine Specifications

Use the Machine Spec tab to attach documentation:

- Equipment manuals (PDF)

- Setup instructions

- Quality specifications

- Safety procedures

- Photos or diagrams

This keeps all process-related documentation in one place, accessible to operators and engineers.

4. Job Template Creation

Job Templates combine multiple Process Templates into complete production sequences. This is your master recipe for making a finished product.

Creating a Job Template

Navigate to Job Template menu and create a new template.

Select the Final Output Item - What finished product does this Job Template produce? The system uses this to link the template to items in the Production Planning Applet.

Save to initialize the template. Now you can define the production routing.

Defining Options (Production Variations)

A single product might have multiple ways to manufacture it—different process sequences, alternative materials, or quality levels. These are called “Options.”

Navigate to the Option tab. The system shows all available Process Templates. Select the ones needed for this production route, and they’ll be sequenced automatically based on their Process Type sequence numbers.

Common Option Scenarios:

- Standard vs Express: Express skips certain quality checks for faster turnaround

- Material Variations: Different processes for steel vs aluminum components

- Quality Levels: Premium products get additional finishing steps

Finalizing the Process Group

Once you’ve selected your Process Templates for an Option:

- Select the Option you want to activate

- Enter a Group Name - typically the output item name or a descriptive variant (“Standard Armored Cable”, “Premium Finish Table”)

- Click Add Group

The system creates the Process Group, which is what appears in the Production Planning Applet when creating Job Orders.

Verify your work in the Process Group tab. You’ll see all Process Templates in sequence, with their input/output requirements. This is what production planners will use to create Job Orders.

5. Configuration Best Practices

Naming Conventions

Consistent naming makes the system easier to use and maintain.

Machines:

[Location]-[Type]-[Number]

Examples:

- MAIN-ARM-A1 (Main facility, Armoring, unit A1)

- BR2-CUT-C3 (Branch 2, Cutting, unit C3)Process Types:

Use clear, standard terms

Good: Cutting, Assembly, Testing, Packaging

Avoid: Proc1, Step2, MiscProcess Templates:

[Department] - [Action] - [Target]

Examples:

- Cable Dept - Armoring - 10mm Cable

- Assembly - Table Legs - Oak

- QC - Testing - Electrical SafetyJob Templates:

[Product Name] - [Variant]

Examples:

- Armored Cable 10mm - Standard

- Office Table - Premium Finish

- Custom Assembly - Client Spec ASequence Number Strategy

Use a consistent numbering scheme for Process Types:

10 - Preparation

20 - Primary Processing

30 - Secondary Processing

40 - Assembly

50 - Testing

60 - Finishing

70 - Packaging

80 - Quality ControlLeave gaps for future insertions. If you need to add a process between Primary (20) and Secondary (30), use 25.

Input/Output Ratio Verification

Before finalizing Process Templates:

- Consult production team - They know the actual material consumption

- Account for waste - If 5% of material is scrap, factor that into input ratios

- Test with small batches - Create a Job Order and verify actual vs planned consumption

- Review regularly - Update ratios as processes improve or materials change

Documentation Standards

For Machine Specifications:

- File naming: Use descriptive names (ARM-A1-Manual.pdf, not doc1.pdf)

- Version control: Include dates or version numbers

- Accessibility: Ensure operators can access from the factory floor

- Updates: Review and update annually or when equipment changes

6. Common Issues

Can’t find an item when adding inputs/outputs?

- Item doesn’t exist in Item Data Hub

- Item not activated in Doc Item Maintenance

- Check item code spelling

Process Templates appear in wrong order in Job Template?

- Check Process Type sequence numbers

- Adjust sequence to change order

- Remember: lower numbers execute first

Can’t save Job Template?

- No default machine selected in Process Templates

- Missing input or output items

- Process Group name already exists

Material consumption doesn’t match actual usage?

- Input/output ratios incorrect

- Review ratios with production team

- Account for waste and scrap

- Update Process Template ratios

Job Template doesn’t appear in Production Planning Applet?

- Process Group not created (must click “Add Group”)

- Output item doesn’t match item in Job Order

- Job Template not saved properly

7. Integration with Production Planning

Once your Process Maintenance configuration is complete, here’s how it flows into production:

In Production Planning Applet:

- Planner creates a Job Order

- Selects an item to produce

- System shows available Job Templates (Process Groups) for that item

- Planner selects a Job Template

- Clicks “Generate Process Instance”

- System creates individual Process Instances from your Process Templates

- Each Process Instance includes:

- Machine assignment (from your default machine)

- Input requirements (from your input ratios)

- Expected outputs (from your output ratios)

- Sequence (from your Process Type sequence)

Your configuration drives:

- Material requirements planning

- Machine capacity planning

- Production costing

- Inventory transactions

- Work instructions for operators

8. Quick Reference

Configuration Sequence

- Create Machines (one-time setup)

- Create Process Types (one-time setup, define sequence)

- Create Process Templates (for each manufacturing step)

- Define inputs and outputs

- Assign machines

- Set ratios

- Create Job Templates (for each finished product)

- Select output item

- Define Options

- Create Process Groups

Key Relationships

| Element | Contains | Used By |

|---|---|---|

| Machine | Equipment specs | Process Templates |

| Process Type | Sequence number | Process Templates |

| Process Template | Inputs, outputs, machines | Job Templates |

| Job Template | Process sequence | Production Planning (Job Orders) |

Checklist Before Going Live

- All machines defined with clear names

- Process Types created with logical sequence numbers

- Process Templates created for all manufacturing steps

- Input/output ratios verified with production team

- Default machines assigned

- Job Templates created for all products

- Process Groups finalized

- Test Job Order created in Production Planning

- Actual vs planned consumption verified

- Documentation uploaded to Machine Specs